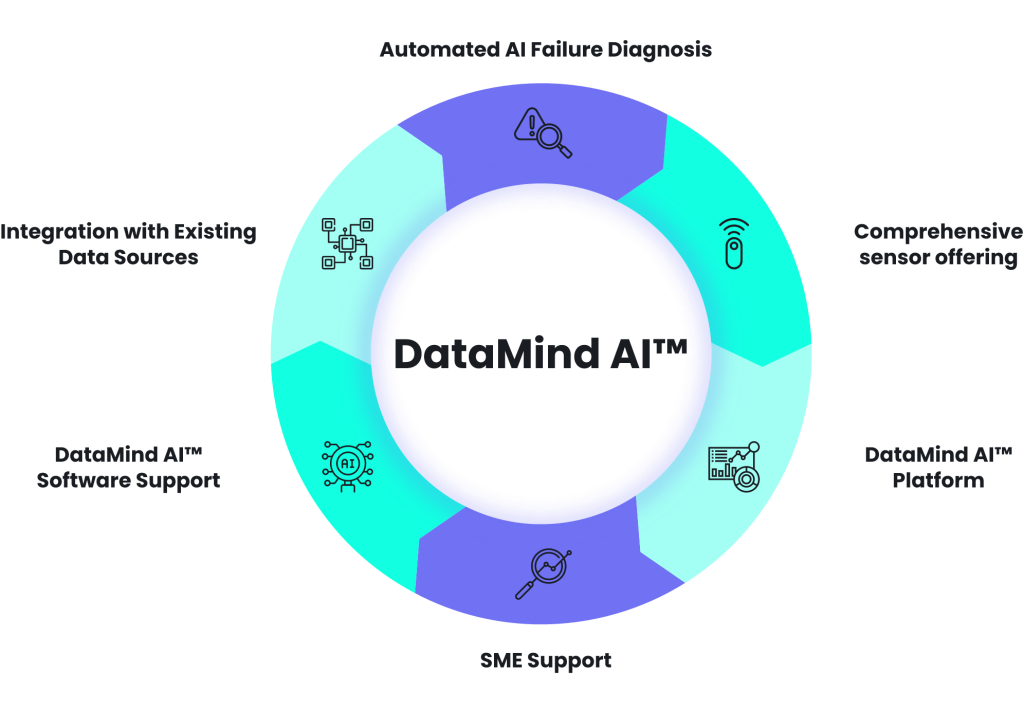

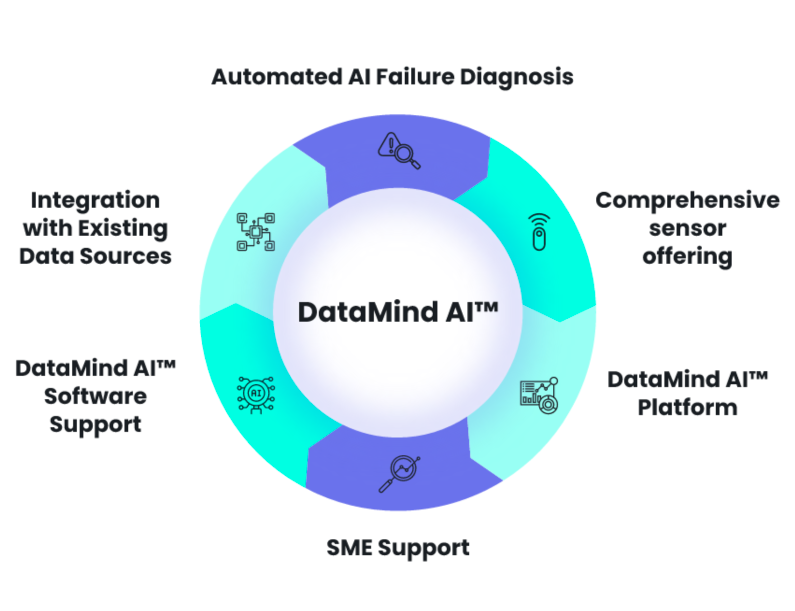

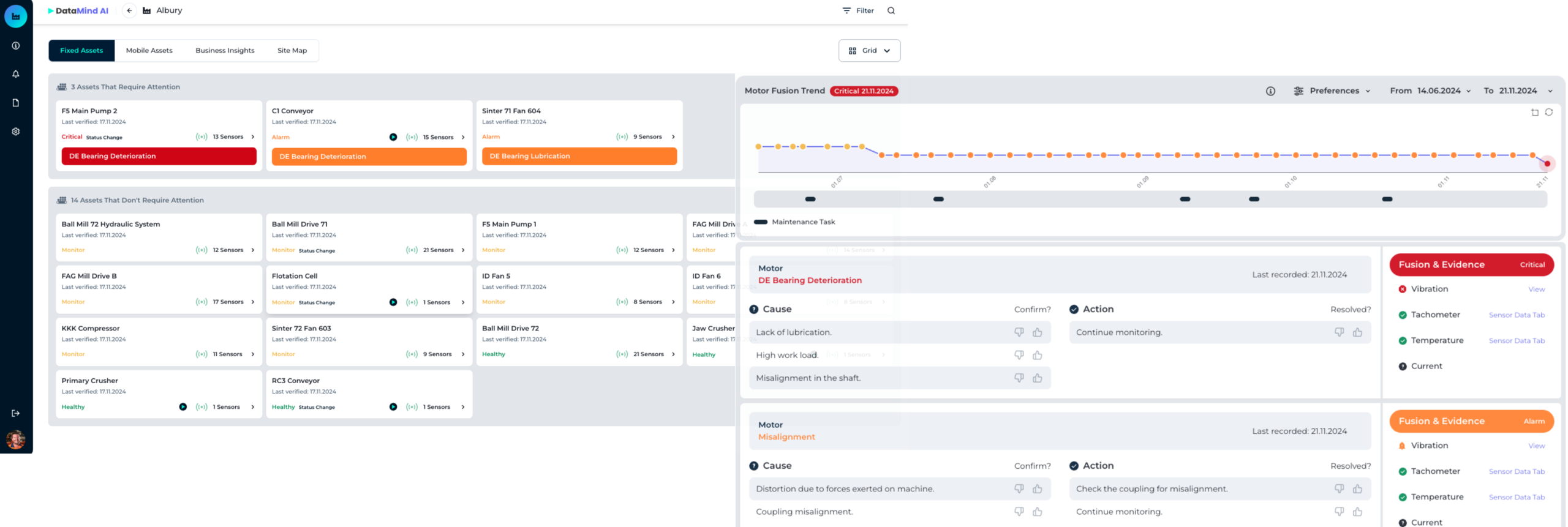

All your Predictive Maintenance requirements in a single out-of-the-box solution

Powered by the cutting-edge AI Sensor Fusion Technology, the DataMind AI™ system provides comprehensive insights into equipment health by identifying the failure mode, pinpointing its location, and analyzing the root cause to prevent recurrence. It also assesses the severity of the issue, ensuring that critical problems are prioritized.

Finally, the system delivers recommended actions for maintenance teams, enabling precise, data-driven decisions to enhance reliability and operational efficiency.

DataMind™ delivers an advanced sensor suite tailored for harsh mining environments, integrating vibration, oil, temperature, pressure, current, tachometers, and cameras to enable accurate failure detection and root cause analysis. The platform supports both wired and wireless sensors and enhances existing infrastructure by filling sensor gaps.

With over 200 years of combined Condition Monitoring experience, our SMEs bring deep knowledge of the mining sector, ensuring tailored 24/7 support that addresses industry-specific challenges. We activate local support teams and collaborate with trusted partners, and vendors already familiar with the mining sites, guaranteeing seamless implementation and reliable ongoing support.

DataMind AI is backed by comprehensive software support, ensuring seamless operation and continuous optimization. Our dedicated support teams provide proactive monitoring, regular updates, and rapid issue resolution to minimize downtime and maintain peak system performance. Our experts guide users on how to fully leverage the platform and its data for informed decision-making and enhanced operational efficiency.

Belt conveyors

Drives

Reclaimers

Stackers

Shiploaders

Cone crushers

Jaw crushers

AG mills

Blowers

Screens

HPGRs

Mills

Ball mills

SAG mills

Flotation cells

Blast furnaces

Agitators

Sifters

Thickeners

Rotary Kilns

Rolling mills

Rollers

Cooling tower fans

Cyclones

Draglines

Heat exchangers

Filters

Centrifugal Pumps

Reciprocating Pumps

Rotary Pumps

ID Fans

FD Fans

Sinter fans

Pre-furnace fans

Compressors

Dust collectors