July 9, 2025

We’re proud to share Razor Labs‘ highlights from Q2 2025 – a quarter marked by strategic growth, real-world impact, and deeper global engagement. Powered by AI and guided by our mission to advance predictive maintenance, we continue to turn insights into action.

From award-winning innovation to new deployments and field success stories, our momentum is accelerating across industries, regions, and reliability teams.

Innovation & Product Milestones

Razor Labs Launches DataMind AI 4.1 – Smarter Diagnostics, Faster Decisions

“Every feature in version 4.1 is designed with a singular focus: empowering reliability and maintenance experts to achieve faster insights, better decisions, and earlier interventions.” – Assaf Eden, VP Product

Read more>>

Industry Recognition

Another major win for Razor Labs!

We’re proud to be named a winner of the 2025 Industrial IoT Product of the Year Award, presented by AIoT World Expo and TMC.

This recognition celebrates the innovation behind DataMind AI™. Read more >>

Real-World Impact

This quarter, DataMind AI™ helped maintenance teams detect faults early, reduce downtime, and protect critical operations.

Here are real-world case studies from Q2 2025 showing AI-driven maintenance in action.

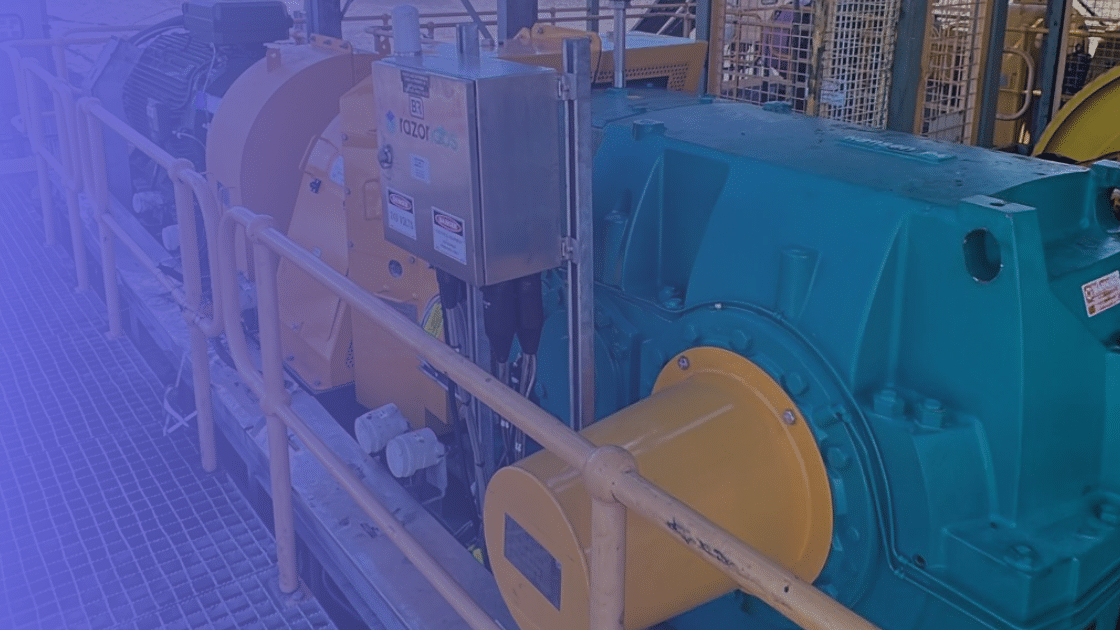

Sensor Fusion Identifies Mechanical Degradation in Sinter Fan Before Failure

- Unplanned downtime prevented: 7 hours

- Estimated loss savings: $336,000

- Download the full case study here>>

DataMind AI™ Prevents Conveyor Motor Failure by Detecting Hidden Bearing Fluting

- Unplanned downtime prevented: 10 hours

- Estimated savings: $191,000

- Download the full case study here >>

Early Detection of Bearing Failure in a Critical Pump Using DataMind AI™

- Unplanned downtime prevented: 4 hours

- Estimated savings: $180,000

- Download the full case study here >>

Visual AI Detects Crusher Liner Wear and Prevents Production Risks

- Unplanned downtime prevented: 5 hours

- Estimated savings: $275,000

- Download the full case study here >>

AI in Mining: Razor Labs Featured on Top Podcasts

Our Co-Founder & CTO Michael Zolotov, joined host Adrian Pocobelli to explore how AI Sensor Fusion is redefining predictive maintenance in mining.

Listen here >>

Michael Zolotov, Co-Founder & CTO joined host Ryan Chacon to discuss the role of AI and IoT in mining. The episode covered predictive maintenance and scaling AI in industry.

Listen here >>

Industry Events

SACEA Regional Meeting 2025

Razor Labs joined the SACEA Regional Meeting on April 23, 2025, where CTO & Co-Founder Michael Zolotov presented how AI-driven condition monitoring is transforming coal mining maintenance in South Africa. Read more >>

Global Resources Innovation Expo

Razor Labs participated in GRX25 in Brisbane, showcasing DataMind AI™ and being named a finalist for the Outstanding Innovative METS Company Award, alongside industry leaders shaping the future of mining.

Read more >>

Featured In

Mining Technology Magazine

In-depth interview with Tomer Srulevich, our CBO, exploring how DataMind AI™ is transforming predictive diagnostics and safety across mining sites. Read more >>

Mining.com.au

Razor Labs was named a finalist for the Outstanding Innovative METS Company Award at GRX25 – covered by Mining.com.au, highlighting our role in driving operational transformation in the sector. Read more >>

Australian Mining Magazine

Our work in predictive maintenance was spotlighted in Australian Mining’s, showcasing the measurable impact of AI-driven maintenance in real-world operations. Read more >>